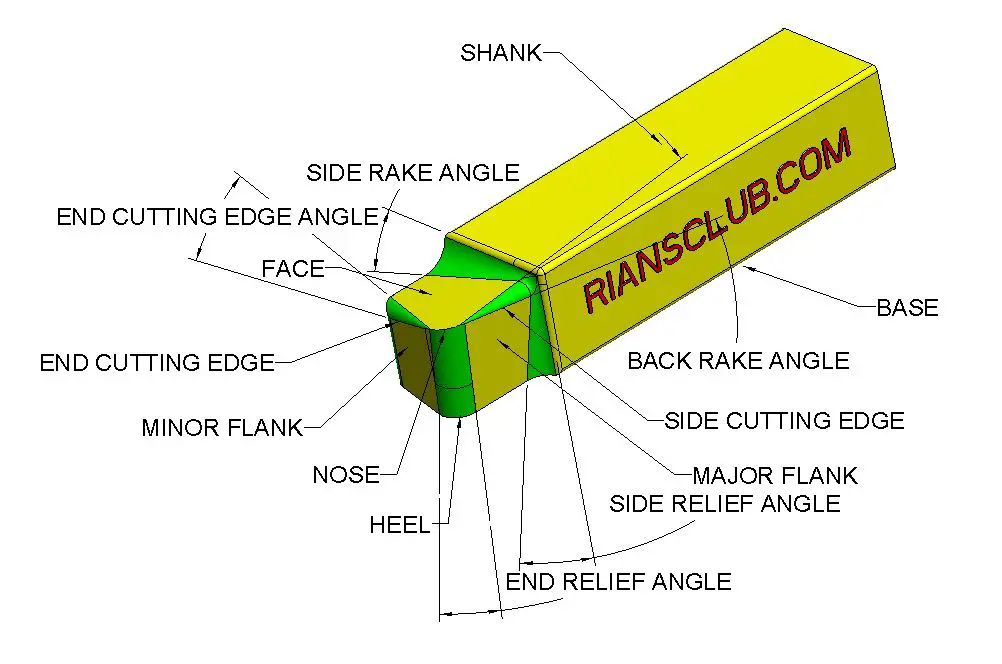

What Is Shank In Cutting Tool . the shank end of the drill bit is the end by which the bit is held and driven. The tool handle affects concentricity and dynamic balance, and. The shank is the portion of the reamer by which it is held and driven. A straight shank is a cylindrical shank. the shank is the connection between the machine tool spindle and the cutting tool. a machine taper is essential for ensuring accuracy in machining by precisely connecting cutting tools to a machine’s spindle. If the tool is an. cutting tool surfaces and elements are shank, flank face, rake face, cutting edge, cutting wedge, etc. machine tool shanks, often referred to simply as “shanks,” are the interface between the machine spindle and the cutting tool. In this guide, you’ll learn how. Shank is the main body of the tool.

from www.riansclub.com

The shank is the portion of the reamer by which it is held and driven. If the tool is an. Shank is the main body of the tool. the shank end of the drill bit is the end by which the bit is held and driven. the shank is the connection between the machine tool spindle and the cutting tool. A straight shank is a cylindrical shank. machine tool shanks, often referred to simply as “shanks,” are the interface between the machine spindle and the cutting tool. The tool handle affects concentricity and dynamic balance, and. cutting tool surfaces and elements are shank, flank face, rake face, cutting edge, cutting wedge, etc. a machine taper is essential for ensuring accuracy in machining by precisely connecting cutting tools to a machine’s spindle.

Single Point Cutting Tool Definition, Geometry, Nomenclature, And Angle

What Is Shank In Cutting Tool the shank is the connection between the machine tool spindle and the cutting tool. The shank is the portion of the reamer by which it is held and driven. cutting tool surfaces and elements are shank, flank face, rake face, cutting edge, cutting wedge, etc. the shank is the connection between the machine tool spindle and the cutting tool. The tool handle affects concentricity and dynamic balance, and. Shank is the main body of the tool. If the tool is an. In this guide, you’ll learn how. a machine taper is essential for ensuring accuracy in machining by precisely connecting cutting tools to a machine’s spindle. the shank end of the drill bit is the end by which the bit is held and driven. machine tool shanks, often referred to simply as “shanks,” are the interface between the machine spindle and the cutting tool. A straight shank is a cylindrical shank.

From www.mech4study.com

Single Point Cutting Tool Nomenclature, Angle,Geometry and Signature mech4study What Is Shank In Cutting Tool In this guide, you’ll learn how. The shank is the portion of the reamer by which it is held and driven. the shank is the connection between the machine tool spindle and the cutting tool. The tool handle affects concentricity and dynamic balance, and. the shank end of the drill bit is the end by which the bit. What Is Shank In Cutting Tool.

From www.youtube.com

Design of Shanks, Cutting Tip Design of Single Point Cutting Tools YouTube What Is Shank In Cutting Tool the shank is the connection between the machine tool spindle and the cutting tool. If the tool is an. machine tool shanks, often referred to simply as “shanks,” are the interface between the machine spindle and the cutting tool. cutting tool surfaces and elements are shank, flank face, rake face, cutting edge, cutting wedge, etc. the. What Is Shank In Cutting Tool.

From www.indiamart.com

Straight Shank Korloy Cutting Tool, For CNC Machine at Rs 200 in Bhiwandi What Is Shank In Cutting Tool A straight shank is a cylindrical shank. the shank end of the drill bit is the end by which the bit is held and driven. In this guide, you’ll learn how. the shank is the connection between the machine tool spindle and the cutting tool. The tool handle affects concentricity and dynamic balance, and. machine tool shanks,. What Is Shank In Cutting Tool.

From cuttingtoolpickers.com

11/16" 2 Flute Double End End Mill HSSCo Sowa 103210 (3/4" Shank) — Cutting Tool Pickers What Is Shank In Cutting Tool The tool handle affects concentricity and dynamic balance, and. In this guide, you’ll learn how. A straight shank is a cylindrical shank. the shank end of the drill bit is the end by which the bit is held and driven. If the tool is an. a machine taper is essential for ensuring accuracy in machining by precisely connecting. What Is Shank In Cutting Tool.

From boroburrs.com

14Shanks1 What Is Shank In Cutting Tool A straight shank is a cylindrical shank. The shank is the portion of the reamer by which it is held and driven. The tool handle affects concentricity and dynamic balance, and. the shank is the connection between the machine tool spindle and the cutting tool. the shank end of the drill bit is the end by which the. What Is Shank In Cutting Tool.

From www.alamy.com

Woodworking shank router bit. Shaping copy milling cutter with ball bearing. Rotating cutting What Is Shank In Cutting Tool the shank end of the drill bit is the end by which the bit is held and driven. Shank is the main body of the tool. the shank is the connection between the machine tool spindle and the cutting tool. A straight shank is a cylindrical shank. In this guide, you’ll learn how. a machine taper is. What Is Shank In Cutting Tool.

From www.aliexpress.com

Thread milling cutter shank tool shank threaded shank single blade SMT12 12F11 18 20K16 25 25M16 What Is Shank In Cutting Tool the shank is the connection between the machine tool spindle and the cutting tool. The tool handle affects concentricity and dynamic balance, and. machine tool shanks, often referred to simply as “shanks,” are the interface between the machine spindle and the cutting tool. a machine taper is essential for ensuring accuracy in machining by precisely connecting cutting. What Is Shank In Cutting Tool.

From www.ebay.com.au

45 Degree 1/4 Inch Shank Cutting Tool Woodworking Door Engraving eBay What Is Shank In Cutting Tool Shank is the main body of the tool. the shank is the connection between the machine tool spindle and the cutting tool. cutting tool surfaces and elements are shank, flank face, rake face, cutting edge, cutting wedge, etc. a machine taper is essential for ensuring accuracy in machining by precisely connecting cutting tools to a machine’s spindle.. What Is Shank In Cutting Tool.

From jag-mfg.com

Weldon Shank 4 Flutes TiCN Monolayer Finish 0.2813 Cutting Diameter 3.1250 Overall Length 0.3750 What Is Shank In Cutting Tool machine tool shanks, often referred to simply as “shanks,” are the interface between the machine spindle and the cutting tool. A straight shank is a cylindrical shank. the shank end of the drill bit is the end by which the bit is held and driven. a machine taper is essential for ensuring accuracy in machining by precisely. What Is Shank In Cutting Tool.

From www.indiamart.com

Straight Shank Cutting Tool Inserts, For Industrial at Rs 95 in Chennai What Is Shank In Cutting Tool a machine taper is essential for ensuring accuracy in machining by precisely connecting cutting tools to a machine’s spindle. Shank is the main body of the tool. If the tool is an. the shank end of the drill bit is the end by which the bit is held and driven. In this guide, you’ll learn how. the. What Is Shank In Cutting Tool.

From www.ebay.com.au

60Degree Shank Cutting Tool Cutting Dia CNC V Bit Woodworking Door Engraving eBay What Is Shank In Cutting Tool cutting tool surfaces and elements are shank, flank face, rake face, cutting edge, cutting wedge, etc. The shank is the portion of the reamer by which it is held and driven. The tool handle affects concentricity and dynamic balance, and. In this guide, you’ll learn how. If the tool is an. machine tool shanks, often referred to simply. What Is Shank In Cutting Tool.

From ebonyedmondstone.blogspot.com

Drillpro 1/2 Inch Shank Double Flute Straight Router Bit Cutter Golden Coated CNC Carbide Wood What Is Shank In Cutting Tool the shank is the connection between the machine tool spindle and the cutting tool. machine tool shanks, often referred to simply as “shanks,” are the interface between the machine spindle and the cutting tool. cutting tool surfaces and elements are shank, flank face, rake face, cutting edge, cutting wedge, etc. The shank is the portion of the. What Is Shank In Cutting Tool.

From www.peaktoolworks.com

High Speed Steel Shank Peak Toolworks What Is Shank In Cutting Tool machine tool shanks, often referred to simply as “shanks,” are the interface between the machine spindle and the cutting tool. Shank is the main body of the tool. The tool handle affects concentricity and dynamic balance, and. a machine taper is essential for ensuring accuracy in machining by precisely connecting cutting tools to a machine’s spindle. the. What Is Shank In Cutting Tool.

From amyspeight.blogspot.com

Drillpro 1/2 Inch Shank Double Flute Straight Router Bit Cutter Golden Coated CNC Carbide Wood What Is Shank In Cutting Tool the shank end of the drill bit is the end by which the bit is held and driven. The shank is the portion of the reamer by which it is held and driven. machine tool shanks, often referred to simply as “shanks,” are the interface between the machine spindle and the cutting tool. The tool handle affects concentricity. What Is Shank In Cutting Tool.

From www.aliexpress.com

HSS long shank cutting tool A type center drilling tool 1x100mm / 3x120mm / 6X150mm extra center What Is Shank In Cutting Tool a machine taper is essential for ensuring accuracy in machining by precisely connecting cutting tools to a machine’s spindle. The tool handle affects concentricity and dynamic balance, and. In this guide, you’ll learn how. machine tool shanks, often referred to simply as “shanks,” are the interface between the machine spindle and the cutting tool. If the tool is. What Is Shank In Cutting Tool.

From www.toolmex.com

Double Angle Shank Type Cutter Results Page 1 Toolmex Industrial Solutions What Is Shank In Cutting Tool The tool handle affects concentricity and dynamic balance, and. machine tool shanks, often referred to simply as “shanks,” are the interface between the machine spindle and the cutting tool. the shank is the connection between the machine tool spindle and the cutting tool. the shank end of the drill bit is the end by which the bit. What Is Shank In Cutting Tool.

From www.themachinedesign.com

Single Point Cutting Tool Nomenclature, Geometry The Machine Design What Is Shank In Cutting Tool cutting tool surfaces and elements are shank, flank face, rake face, cutting edge, cutting wedge, etc. the shank end of the drill bit is the end by which the bit is held and driven. A straight shank is a cylindrical shank. Shank is the main body of the tool. The shank is the portion of the reamer by. What Is Shank In Cutting Tool.

From earthasowers.blogspot.com

end mill shank types Eartha Sowers What Is Shank In Cutting Tool Shank is the main body of the tool. cutting tool surfaces and elements are shank, flank face, rake face, cutting edge, cutting wedge, etc. a machine taper is essential for ensuring accuracy in machining by precisely connecting cutting tools to a machine’s spindle. the shank is the connection between the machine tool spindle and the cutting tool.. What Is Shank In Cutting Tool.